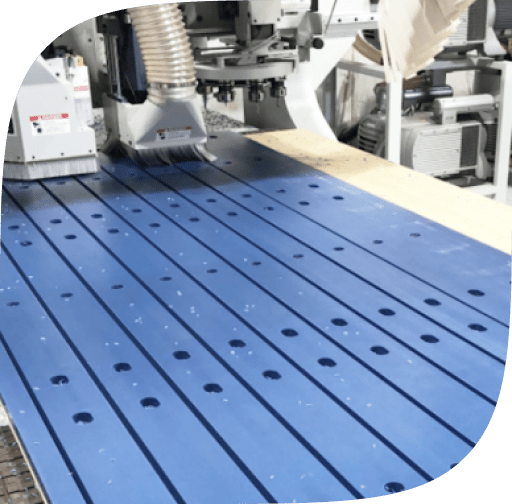

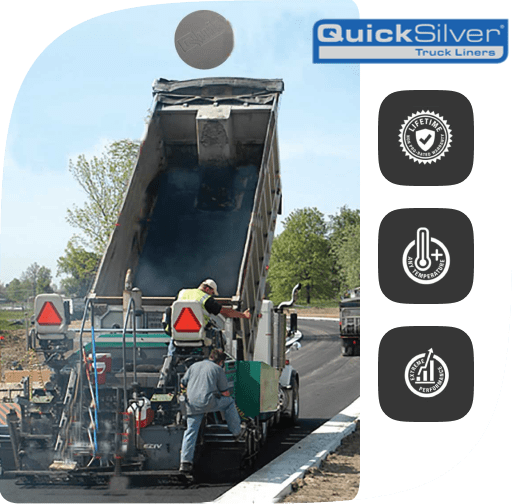

TIVAR 88® Solutions start with Lawrence Industries

TIVAR 88 is a low coefficient friction ultra high molecular weight – polyethylene (UHMW-PE) plastic that offers superior release and non-stick performance properties over traditional UHMMW-PE.

(260) 432-9693